Our Strengths / Competencies

TREL operates principally as an EPC contractor, with an integral teams of competent Engineering, Procurement, Fabrication and Construction personnel.Since our inauguration back in year 1993, we have accomplished a proven track record of safe, quality and timely delivery projects that met with clients' specifications and requirements. Having worked with most of the oil majors, plant owners and MNC contractors in both local and overseas markets, TREL has maintained a core team of efficient and experienced supervision and workforce. Particularly so in Thailand, TREL is more than capable to handle and comply with the local regulatory and statutory requirements, and same time meeting the industry standards and design codes. We have a direct employed team of trained and responsible supervision and competent workforce. We owned our fleet of construction/fabrication machinery and equipment. We constantly explore and adopt latest work methodology including automation and technology in our daily work activities. All of these enable TREL to be less reliance on external contracting parties and thereby assuring better control and successful delivery of our obligations to our valued clients.

Our Advantages

Global Workforce

Ready, Anytime, Anywhere

Our project take place around the region so we have to be able to mobilize the right people where they are needed with greats speed and highest efficiency level. Our group of Company’s global work force (GWF) Scheme unable us to do just that Through GWF, our group of company have grown our own team of engineer and craftsmen who are readily deployed anywhere in the region and attuned to the Rotary Brand of service delivery. To date, we have trained over 1,000 employees to levels of high skills proficiency and it’s our clients who are benefiting from this growing workforce of technical experts We build smart teams.We build smart teams.

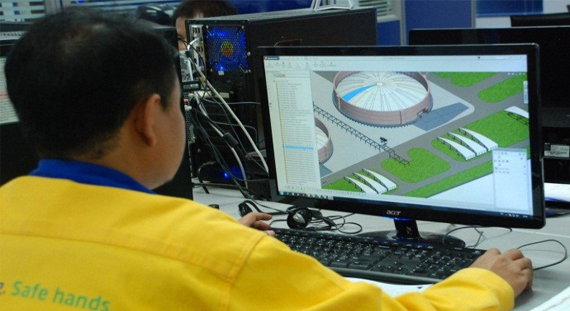

Information Technology

Smart Tools, Smart Designs

When it comes to harnessing technology in our processes, we use the best there is because we believe in working smart. One such technology is the 3D modeling, we can bring our designs to life in 3D right from the drawing board, so you can visualize exactly what the finished site or product will look like.

We also harness SAP Solution to effectively manage all our project processes- We can remain responsive to changes in project scope, costs, risks and schedules.Working smart is our business

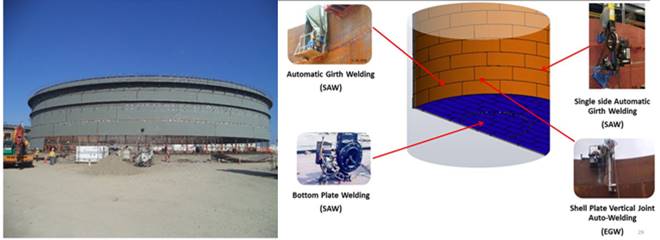

Our construction is planned to ensure safest operations while maximizing quality. Our team is trained and experienced in both conventional and new methodologies. For tank erection, we are not just able to employ the conventional bottom-up method; we are also able to erect top-down using our hydraulic jacking systems. For fabrication, we are equipped with semi-automated welding systems for both vertical & horizontal seams, as well as flat bottom weld seams. We also invested in semi-automatic plasma gouging machines & weld bead shaver machines which speed up the gouging and grinding works, while at the same time, are able to control the surface finish of each weld. In addition, we have inner bore welding machines to provide us with productive butt welding between tube of shell and tube heat exchanger. For the overlay welding of internal walls of pipes, we are able to go down to the smallest diameter of 0.5 to 1 inch with the help of our pipe inner wall welding machines.

Expertise

We know what works,

We understand that in your industry, time is money. This is where our decades of experience in designing and constructing bulk liquid and gas storage facilities differentiates us. Our expertise builds from pre-planning, construction work instruction (CWI), layout optimization & tank configuration, practical & effective solutions to your operational needs, execution and deployment of customized construction techniques for local regulatory and climatic conditions, helping you to save time. It’s all down to smart planning

Safety & Quality

It’s always people first

At Thai Rotary, we take care of our people. That’s why we insist on the most stringent of safety processes at every stage of production, on and off site. By employing our people on a direct basis, we are better able to control quality and work in a safe working environment through regular safety training courses.

We commit of the highest standards of regulatory practices, because protecting our client’s people and assets are our top priority. Our people know that it’s smart to work safe

Capabilities

We are able to provide a wide range of services covering both the field construction and shop fabrication works.

On the field work front, we are competent in delivery EPC services for all types of storage tanks for the oil & gas, petrochemical, water and others products in accordance with the relevant API design codes. The tank design storage conditions be it the ambient design temperature and/or low temperature are also in our range of services. On the shop fabrication front, we are capable to fabricate most of the static equipment such as shell & tube heat exchangers, fin tube exchanger, low and high pressure vessel, column, etc.

Facilities

Our workshop & head office are both located in Banchang, Rayong, Thailand.

| Workshop with shelter | 8,288 | 10 units of overhead cranes capacity up to 20T, 3 units of hydraulic press that can form plate up to 100mm thickness, X units of plate rollers that can roll plate up to 35 mm thick & 3,000 mm width, X unit of head spinning machines for ellipsoidal head & tori spherical head, X unit of CNC plate cutting for both carbon steel & stainless steel, X units of CNC plate drilling for tube sheet & baffle plate for thickness up to 120 mm & 2,000 mm diameter, X units of automatic blasting machines, testing equipments for PMI, UT phase array and Borescope |

| Blasting shop | 540 | |

| Painting yard | 1,500 | |

| Warehouse | 1,600 | |

| Access | By road |

People Development

Human is important is important resources in our organization.

Therefore, TREL continuously developing our peoples in term of provide training, seminar, teambuilding, etc. to improve our important resources in knowledge, awareness, competency and teamwork.

- Training as per Law: We provided training courses as per law and customer’s requirement

- Improve of teamwork : To understand the importance of working as team to achieve organization goals

- Improve English language skills : Improve the efficiency of our workforce with greater confidence in communication in English language, in preparation for any overseas project assignments

- Improve of Worker’s Dual-Skills : Improve efficiency of permanent skills worker (Dual-Skills)

- Energy Conservation : To aware in Energy Conservation